UltiMaker S6 3D Printer

Introducing the UltiMaker S6, the latest innovation in professional 3D printing designed to meet the evolving needs of businesses and educational institutions. Building on UltiMaker’s legacy of reliability and precision, the...

Frequently Bought Together

Introducing the UltiMaker S6, the latest innovation in professional 3D printing designed to meet the evolving needs of businesses and educational institutions. Building on UltiMaker’s legacy of reliability and precision, the S6 offers enhanced performance, expanded material compatibility, and smart automation features that streamline the printing process. Whether you're prototyping in a fast-paced design environment or fostering hands-on learning in the classroom, the UltiMaker S6 delivers the consistency, versatility, and ease of use that professionals and educators demand.

Features

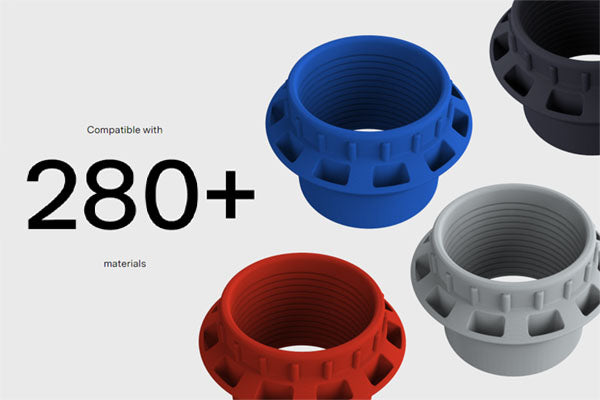

Large Material CompatibilityThe UltiMaker S6 simplifies 3D printing, offering compatibility with a broad range of materials—from advanced engineering polymers to eco-friendly recycled filaments—making it ideal for real-world applications of all kinds. |

|

|

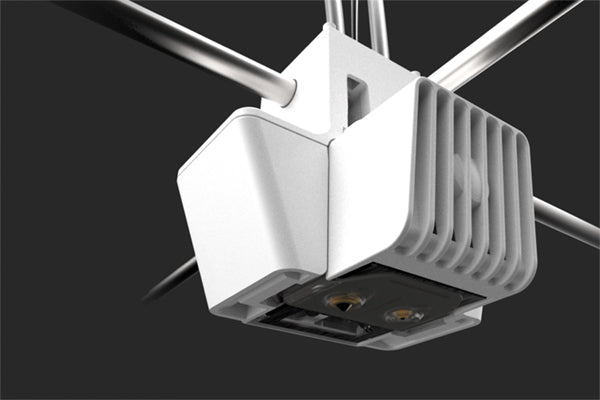

High Flow Print CoresOptimize your printing experience and minimize downtime with Ultimaker's interchangeable, compatible print cores. Easily swap cores and use a variety of materials without interruption thanks to tailored nozzle geometries for different types of materials. The new AA+ anc CC+ cores have a new quad-chamber design, allowing for 2.5x more flow! |

Auto Nozzle Lifting SystemThe innovative dual auto-nozzle lifting system automatically raises and lowers the second nozzle, keeping it out of the way while you print with the other core. This prevents contamination and eliminates potential crashes when using two materials. |

|

|

Multi Material PrintingEmpower your printing with the UltiMaker S6's dual extrusion capabilities, allowing you to print with multiple materials and easily dissolve support structures. This innovative technology enables you to print complex designs with ease, maintaining high quality and reducing the risk of damage during support removal. |

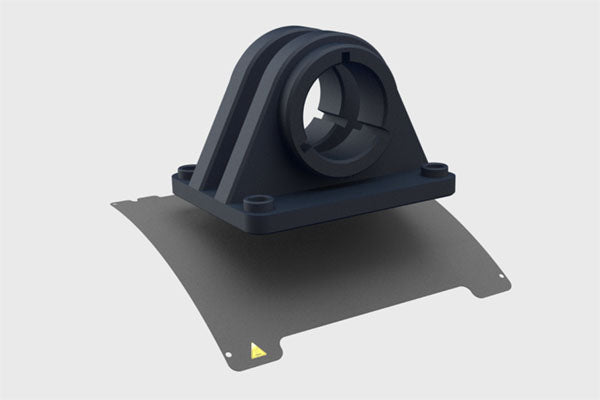

Flexible Build PlateMake printing even easier with the PEI-coated flexible build plate, which eliminates the need for glue and allows you to effortlessly remove parts. The patent-pending design includes 25 magnets and 4 pins for perfect alignment, saving time and increasing productivity with the S6. |

|

|

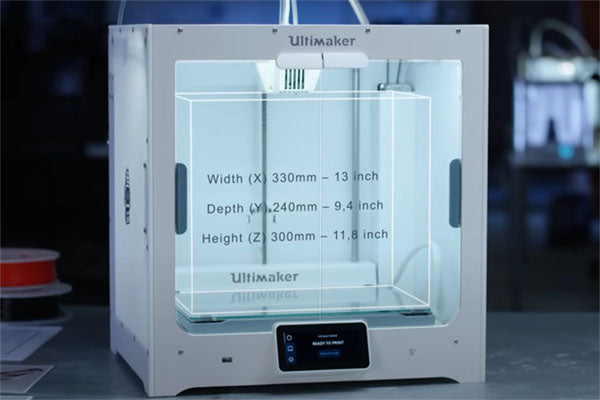

Large Build VolumeThe UltiMaker S8, S7 & S6 have the same build volume of 330 x 240 x 300 mm, making it perfect for large projects and batch printing. You can use the full width of the build volume with both single and dual extrusion, making it ideal for prototyping and design work. |

Composite CompatibleWith the dual-geared, abrasion-resistant feeder, coupled with Ultimakers CC Red 0.6 print core (sold separately), the Ultimaker S6 is capable of printing advanced composite and fiber-filled materials like PA6-CF and PA6-GF filaments. |

|

|

Updated Filament FeederA newly designed hardened feeder module, adapted from the Factor 4, delivers enhanced grip and superior material control—even at high printing speeds. |

Air Manager Add-OnThe Air Manager promotes a secure and regulated workplace by creating an enclosed, internal airflow for the UltiMaker S6 3D printer. This maintains a steady ambient temperature for engineering plastics. The E10 filter effectively captures up to 95% of ultrafine particles (UFPs) released during 3D printing and creates a safe, physical barrier for the print area. |

|

|

Material Station Add-OnThis innovative handling solution accommodates up to six material spools in a humidity-controlled chamber. Smart features take care of filament management, automatically switching to the next available spool of the same type if an issue arises. Designed for seamless integration with the UltiMaker S5 and equipped with composite-ready feeder wheels and filament flow sensors, the Material Station is the ultimate solution for maximizing productivity day and night. |

Weights & Dimensions

- Weight: 29.1 kg

- Dimensions: 495 x 585 x 780 mm

- Build Volume: 330 x 240 x 300 mm

- Compatible Filament Diameter: 2.85mm

Printer Properties

- Print Technology: FDM

- Layer Resolution: 0.25 mm nozzle: 150 - 60 micron | 0.4 mm nozzle: 200 - 20 micron | 0.6 mm nozzle: 300 - 20 micron | 0.8 mm nozzle: 600 - 20 micron

- XYZ Resolution: ± 0.15 mm ± 0.15% feature nominal length

- Feeder Type: Dual-geared feeder, reinforced for composite materials

- Display: 4.7-inch colour touchscreen

- Print Core Replacement: Swappable print cores

- Print Head: Dual extrusion print head with an auto-nozzle lifting system, swappable print cores.

- Nozzle Diameters: 0.25 mm | 0.4 mm | 0.6 mm | 0.8 mm

- XY Speed: Up to 500 mm/s,

- Acceleration: Up to 50,000mm/s²

- Extrusion Flow: Up to 35 mm³/s

Operation Parameters

- Maximum Power Output: 500 W

- Nozzle Temperature: Up to 340 °C

- Nozzle Heat Up Time: < 2 minutes

- Operating Sound: < 51 dBA

- Build Plate Leveling: Advanced active leveling with more accurate inductive sensors

- Build Plate: PEI-coated flexible steel build plate | (Optional glass build plate)

- Build Plate Heat Up Time: < 5 minutes (from 20 to 60 °C)

- Operating Ambient Temperature: 15 - 32 °C

- Non-Operating Temperature: 0 - 32 °C

Ecosystem

- Supplied Free Software:

- UltiMaker Cura – print preparation software

- UltiMaker Digital Factory – printer management software

- UltiMaker Essentials – enterprise-grade online software tools

- Supported OS: MacOS | Windows | Linux

- Plugin Integration: SolidWorks | Siemens NX | Autodesk Inventor

- Supported File Types:

- UltiMaker Cura - STL | OBJ | X3D | 3MF | BMP | GIF | JPG | PNG

- Printable Formats - G | GCODE | GCODE.gz | UFP

- File Transfer: Wi-Fi (2.4 GHz & 5 GHz) | Ethernet | USB

Safety & Compliance

- Certification: CE | FCC | VPAT | RoHS | REACH | CB | BIS | KC | PSE | RCM | SRRC | MIC | NCC | Safe unattended professional use

- More Information: Learn more about UltiMaker safety and compliance (https://support.makerbot.com/s/article/1667337922159)