UltiMaker PVA Removal Station

The UltiMaker PVA Removal Station makes removing support material a breeze, swiftly dissolving it for efficient and productive printing of intricate designs. Features Remove PVA up to 4x Faster! High-speed water...

Frequently Bought Together

The UltiMaker PVA Removal Station makes removing support material a breeze, swiftly dissolving it for efficient and productive printing of intricate designs.

Features

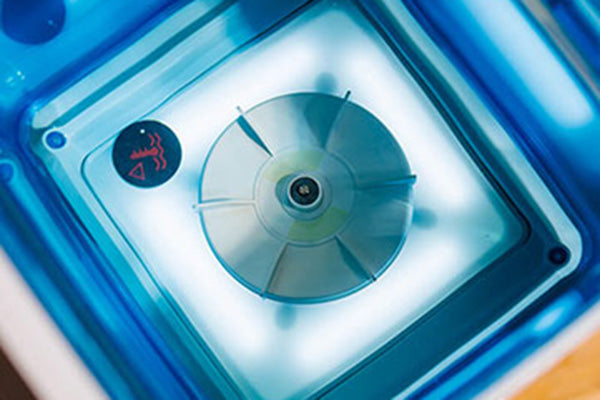

Remove PVA up to 4x Faster!High-speed water circulation driven by a magnetic rotor removes PVA much faster than motionless water – even from hard-to-reach cavities. So you have your parts post-processed and ready to use as soon as possible. |

|

|

Reduce Operator Time up to 80%The PVA Removal Station only takes a few minutes for the operator to use per print and requires almost no maintenance. Simply press the start button, let it spin, and retrieve your print when it's finished. |

Rotor-Powered Water Circulation.Choose the appropriate RPM (100 or 225) for the fragility of your part. The direction of the rotor will alternate every two minutes, providing even water circulation to the model. |

|

|

Prints Stay SubmergedThe rinse basket securely holds your print and keeps it completely submerged during dissolving. When ready, simply lift it for a mess-free draining and print removal. |

Easy to MonitorThis transparent container with built-in illumination makes it easy to keep track of the PVA removal process and determine when your part is ready. The included saturation indicator also helps you know when it's time to refresh the water. |

|

Weight & Dimensions

- Dimensions: 303 x 325 x 374 mm

- Dimensions with Handle Extended: 303 x 325 x 528 mm

- Shipping Box Dimensions: 400 x 400 x 500 mm

- Net Weight: 6.35 kg

- Container Weight (When Empty): 4.2 kg

- Shipping Weight: 8.5 kg

Properties

- Container Volume: 13.7 liters

- Maximum Part Size: 200 x 230 x 165 mm

- Supported Filament: Optimized for - PLA and PVA | Also suitable for: PETG | Tough PLA | Nylon | or CPE in combination with PVA (Also supports equivalent third-party materials)

- Supported Solvents: Water

- Rotor Speed:

- 225 RPM (normal)

- 100 RPM (low)

- Operating Sound: < 50 dBA

Ambient Conditions

- Operating Ambient Temperature: 15 - 32 °C

- Non-Operating Temperature: 0 - 32 °C

- Relative Humidity: 10 - 90% RH non-condensing

Electrical Requirements

- Voltage: 100 - 240 V AC

- Frequency: 50 - 60 Hz

- Power: 38 W