xTool P2 - Conveyor Feeder

The xTool P2 - Conveyor Feeder makes cutting and engraving larger materials up to 3m long a breeze! Equipped with pressure rollers coated in anti-friction material, this device automatically feeds your...

Required products - sold separately

Frequently Bought Together

The xTool P2 - Conveyor Feeder makes cutting and engraving larger materials up to 3m long a breeze! Equipped with pressure rollers coated in anti-friction material, this device automatically feeds your materials so you can work hands-free.

Features

Larger AreaEmpower your engraving capabilities with the xTool P2 - Conveyor Feeder, offering a maximum processing area of 300 x 50 cm. Easily engrave items up to 300 cm in length and increase productivity by creating multiple designs at once. |

|

|

Automatic ConveyingEliminate the need for manual material feeding and eliminate accuracy deviation with automatic engraving path planning and material conveying. |

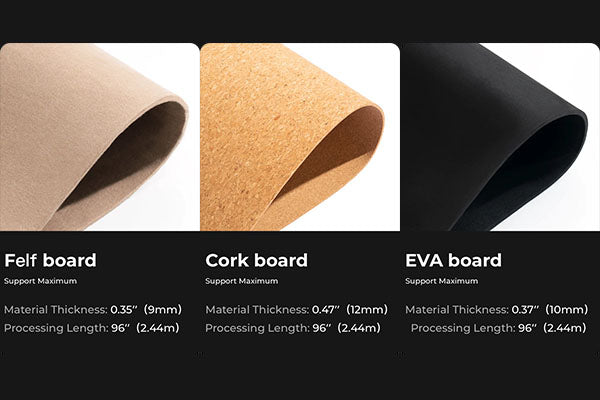

Unrestrained CreationThe range of materials has been expanded to include plywood, acrylic, and fiberboard, as well as softer options like felt, cork, and EVA. |

|

|

High StabilityEquipped with upper and lower pressure wheels that use anti-slip materials, ensuring that materials of various sizes are securely fixed during the conveying process. Say goodbye to slipping and shifting! |

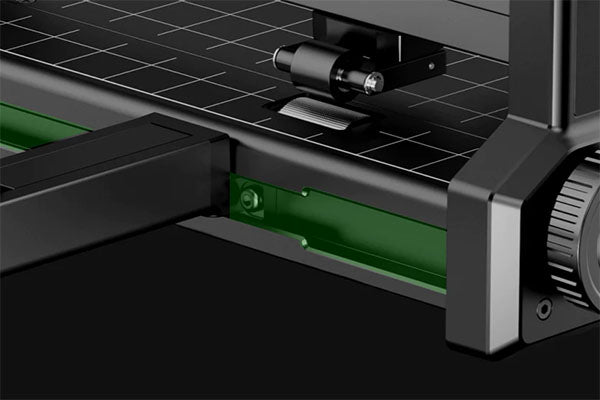

Easier AssemblyIts buckle design allows for easy installation of the conveyor rail, saving you time and hassle. Say goodbye to complicated setups and hello to effortless production. |

|

|

Colour Markings for Pressure SettingThe xTool P2 Conveyor Feeder makes it easy to process various materials by allowing you to quickly adjust the pressure based on the material type. The color markings clearly indicate the appropriate pressure levels for different materials, providing you with a hassle-free experience. |

Easy Positioning AdjustmentEffortlessly adjust the position of materials using the convenient lower knob. |

|

|

Aligning GridsSimply match the grids on the device with your material, and let it smoothly transport in the desired direction. Say goodbye to misaligned and uneven materials. |

Product Info

- Compatible with: xTool P2

- Package Size: 769 x 255 x 230 mm

- Product Size: 687 x 200 x 135 mm

- Product Weight: 8.045 kg

- Max Speed: 160 mm/s

Work Area

- Max Processing Area: 3000 x 500 mm

- Max Material Width: 624 mm

- Min Material Width: 65 mm

- Max Material Thickness: 14 mm

Do the conveyor rails need to be purchased separately?

Two pairs come with the conveyor feeder which can support up to 99cm in length. Add conveyor rails according to the length of material you are using. Make sure that the part of a material hung in the air is no longer than 30 cm.

Unexpected sounds can be heard coming from the pinch rollers, what can I do?

Check whether the pressure of the pinch rollers is set too high. Setting the pressure too high may cause machine faults.

Note: The motors are locked when the lid is closed so you cannot adjust the position of the material. Open the lid of the machine, raise the pinch rollers and then adjust the position of the material.

What is the maximum thickness of plywood supported by the conveyor feeder?

The maximum thickness of plywood supported is 14 mm. When you process a piece of plywood thicker than 9 mm, however, the conveying accuracy significantly depends on the flatness of the plywood. Therefore, to process a piece thicker than 9 mm, you need to ensure that it is flat without warped edges or being twisted.

Can I use corrugated paper on the conveyor feeder?

We advise not to process corrugated paper on the conveyor feeder as to ensure accuracy of conveying, high pressure is required which may damage the surface of the corrugated paper.

How do I clean the conveyor feeder?

- If residues (such as wood chips) accumulate under the pinch rollers, you can turn over the conveyor feeder, and clean the pinch rollers with a brush (such as a toothbrush) while turning the knob.

- If the smoke produced due to material processing is not exhausted in time, the working area may become dirty. You can clean it by using tissues moistened with alcohol.